Additive Masterbatch

IPM is manufacturer and distributer of additive masterbatch & functional materials. They are widely used in cap, basket and plastic container, high filler loading, high scrap and recycle loading, etc. Based on industry know-how and advanced technology, IPM is striving to give integrating solutions on modification of polymers for its domestic and international market.

Functional Performance with Additive Masterbatch

Range of Product

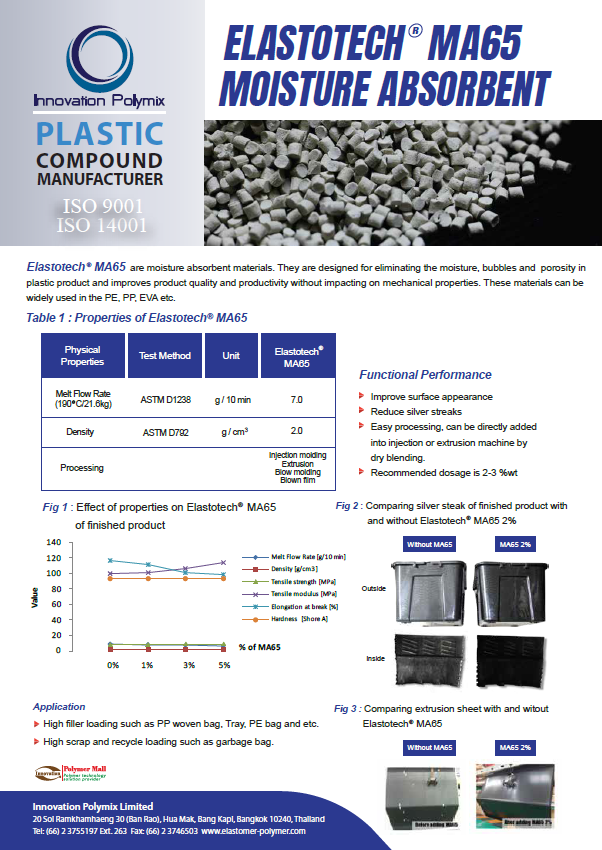

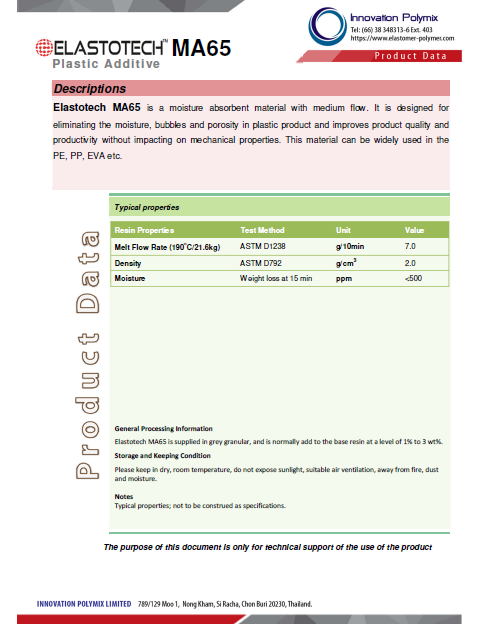

Elastoflex® MA

Elastoflex® MA is moisture absorbent materials. They are designed for eliminating the moisture, bubbles and porosity in plastic product and improve product quality and productivity without impacting on mechanical properties. These materials can be widely used in the PE, PP, EVA etc. and can used in ABS. We can cut off drying step in the process.

Elastoflex® also provides :

- Improve surface appearance

- Reduce moisture streaks or silver streaks

- Easy processing can be directly added into injection or extrusion machine by dry blending.

- Recommended dosage is 2-3 %wt

Application:

- High filler loading such as PP, PE, EVA injection and extrusion.

- High scrap and recycle loading.

Grade

Grade Melt Flow Rate, g/10min

(190°C, 2.16kg)Density, g/cm3 Elastoflex® MA65 7.0 2.0

Datasheet

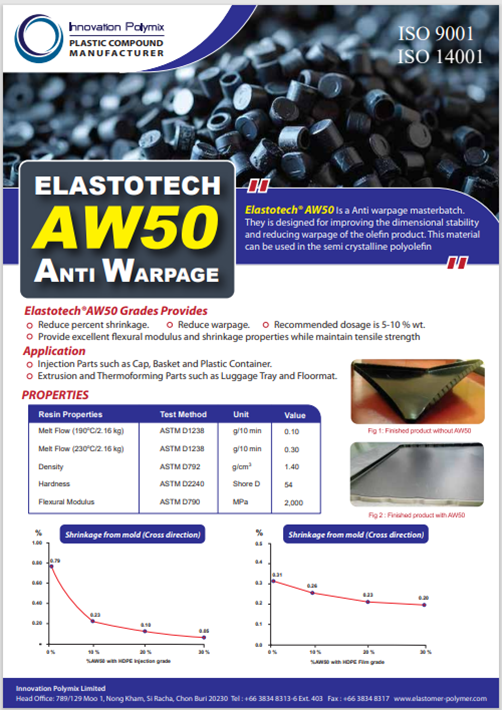

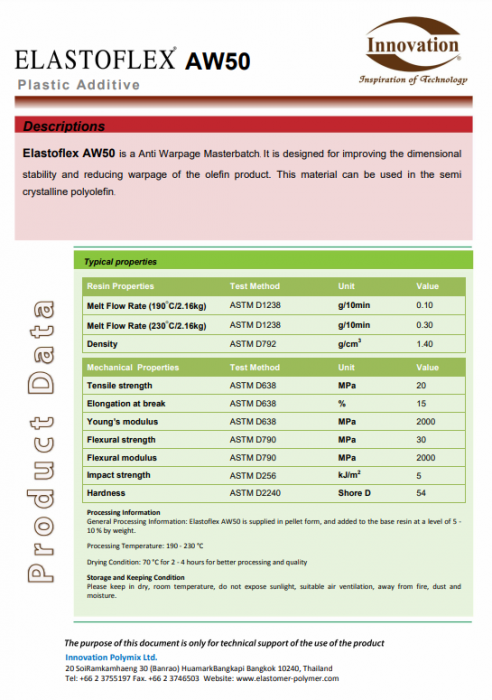

Elastoflex® AW

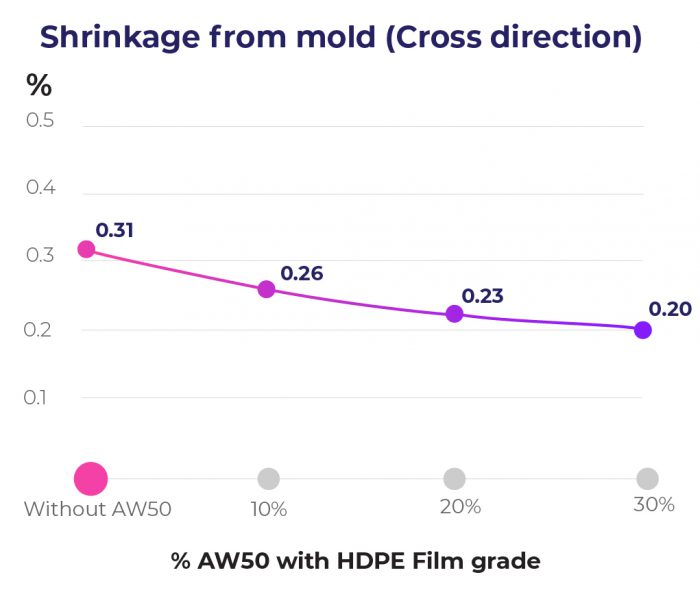

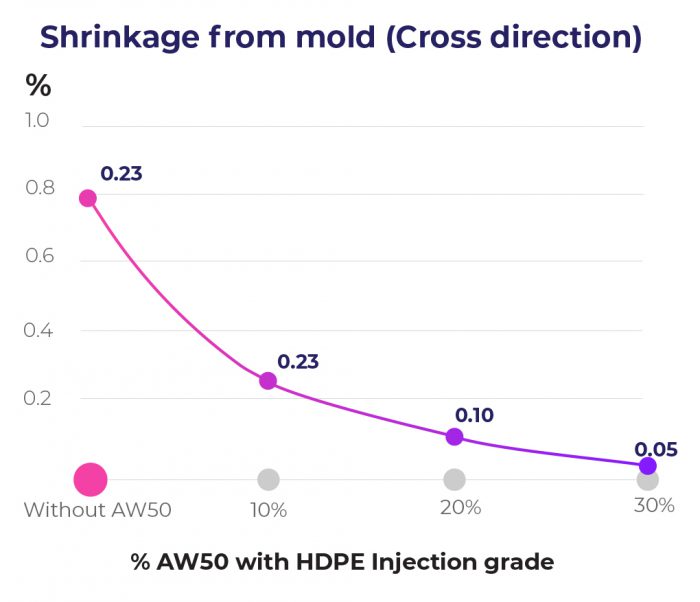

Elastoflex®AW50 Are Anti Warpage Masterbatch. They Are Designed For Improving The Dimensional Stability And Reducing Warpage Of The Olefin Product. This Material Can Be Used In The Semi Crystalline Polyolefin Such As PP PE.

Elastoflex®AW50 Grades Provides:

- Reduce Percent Shrinkage

- Reduce Warpage

- Provides Excellent Flexural Modulus And Shrinkage Properties While Maintain Tensile Strength

- Recommended Dosage Is 5-10 %Wt

Application:

- Injection Parts Such As Cap, Basket And Plastic Container.

- Extrusion And Thermoforming Parts Such As Luggage Tray

Grade

Grade Melt Flow Rate, g/10min

(190°C,21.6 kg)Density, g/cm3 Hardness, Shore D Flexural modulus, MPa Elastoflex® AW50 0.1 1.4 54 2000

Datasheet

Datasheet

Can be used in automotive hose, cable jackets, O-rings, seals, gaskets, industrial belt covers, shoe soles, and compression molding goods.

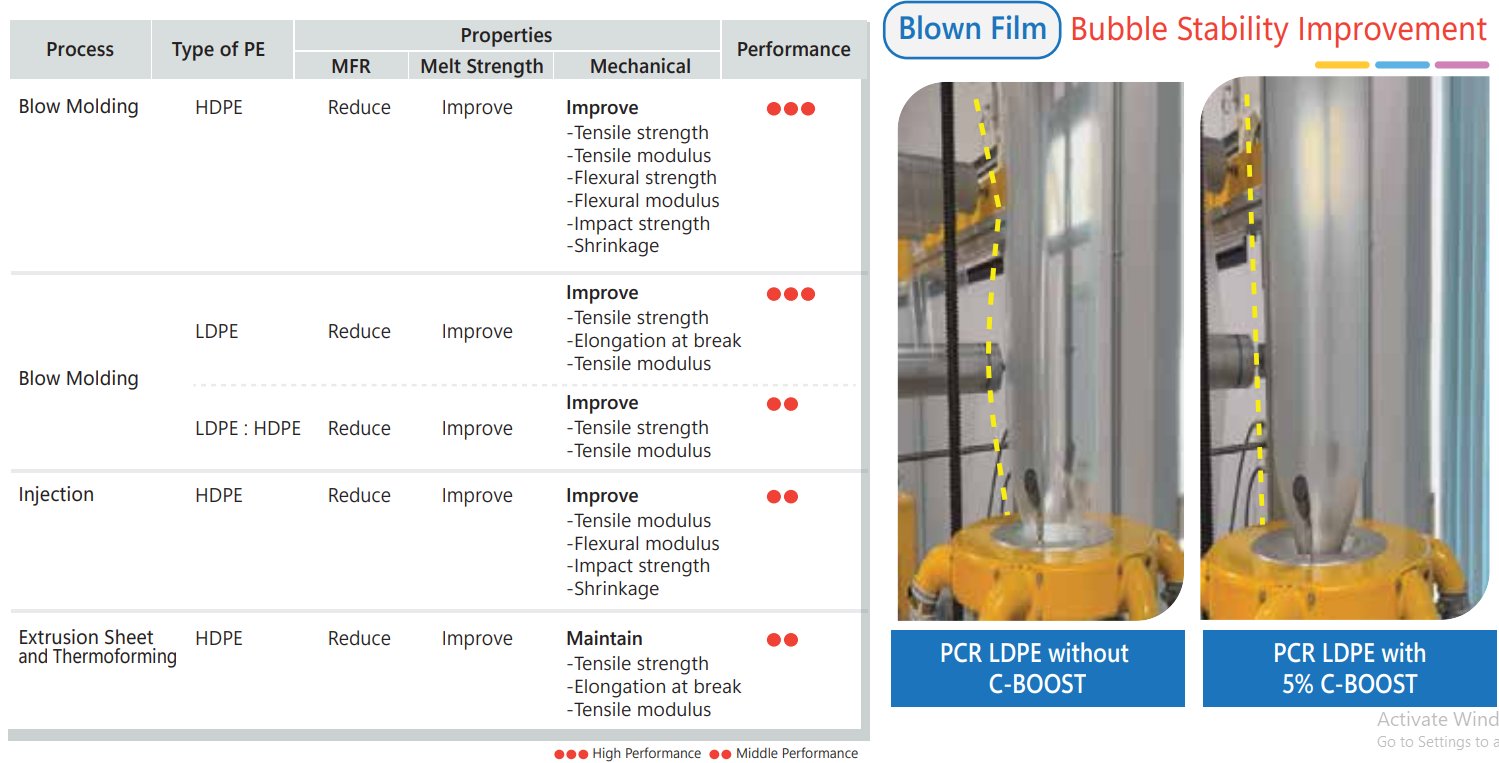

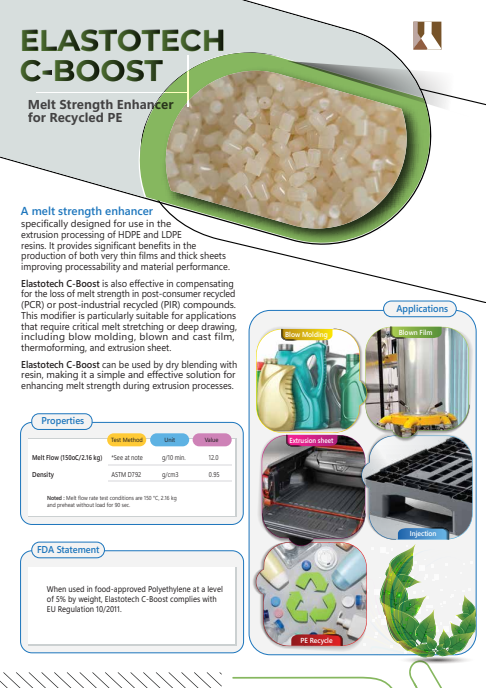

Elastotect® C-Boost

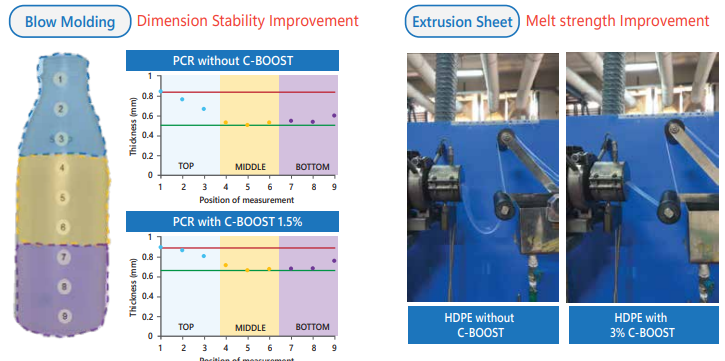

A melt strength enhancer specifically designed for use in the extrusion processing of HDPE and LDPE resins. It provides significant benefits in the production of both very thin films and thick sheets improving processability and material performance.

Elastotech C-Boost is also effective in compensating for the loss of melt strength in post-consumer recycled (PCR) or post-industrial recycled (PIR) compounds. This modifier is particularly suitable for applications that require critical melt stretching or deep drawing, including blow molding, blown and cast film, thermoforming, and extrusion sheet.

Elastotech C-Boost can be used by dry blending with resin, making it a simple and effective solution for enhancing melt strength during extrusion processes.

Test Results – Elastoflex® AW50 with HDPE

Properties :

Test Method Unit Value Melt Flow (150ºC/2.16 kg) *See at note g/10 min. 12.0 Density ASTM D792 g/cm3 0.95 - Grade

When used in food-approved Polyethylene at a level

of 5% by weight, Elastotech C-Boost complies with

EU Regulation 10/2011.

- Grade

When used in food-approved Polyethylene at a level

of 5% by weight, Elastotech C-Boost complies with

EU Regulation 10/2011.

- VALUE PROPOSITION

Datasheet

Do you need any help with our products?

Thank you for visiting Innovation group website. Please provide us your personal details for contacting back.