Materials Product

Rubber compound manufacturing focuses on producing high-quality rubber compounds at reasonable costs to satisfy customer needs. We optimize the rubber processing facilities and combine their experiences to develop and produce rubber compounds, silicone and fluorosilicone compounds for injection molding, compression molding, and extrusion.

A: Standard Polymers

Expert team is experienced in developing polymer solutions that are both flexible and trustworthy.

Elastoflex™ AC-2

Performance

- Blowing under low temperature (Kicker)

- Excellent resistance to ozone, ageing and weather

- Color enhancement

Application

Rubber sponge, EVA sponge sheet, and phylon all can be used.

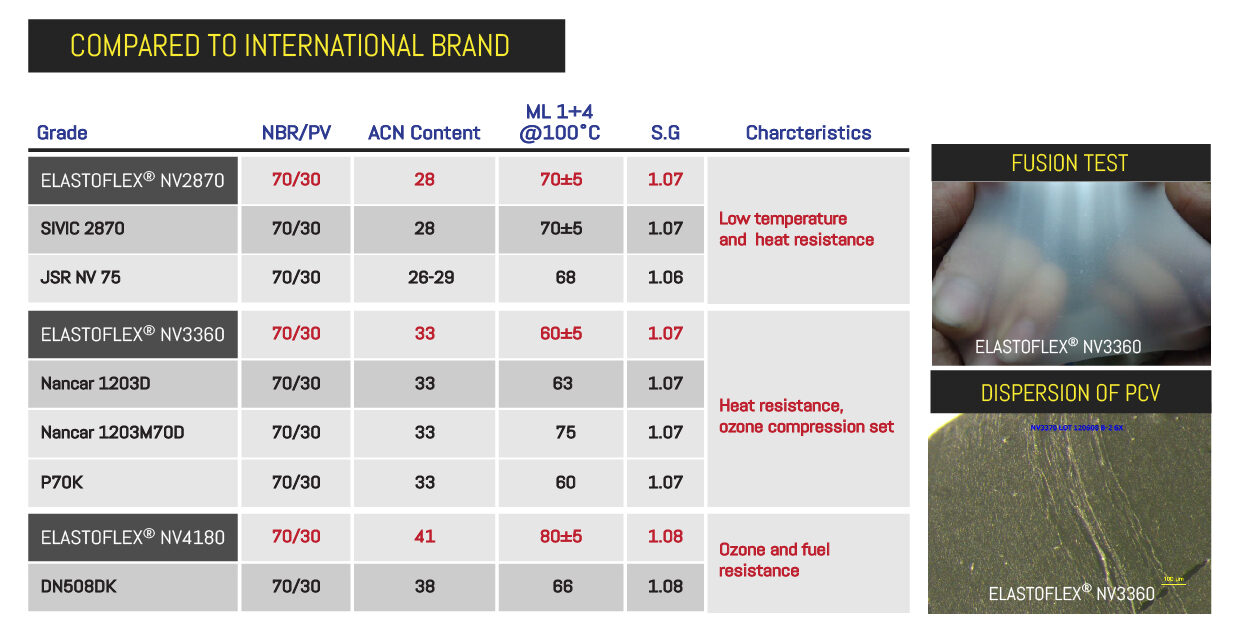

Elastoflex® NV

Elastoflex® NV is a mechanically fully-fluxed blend of 70 parts acrylonitrile-butadiene rubber (NBR) with an acrylonitrile content range from 28% to 41%

Elastoflex® NV2870 is a mechanically fully-fluxed blend of 70 parts acrylonitrile-butadiene rubber (NBR) with 28% acrylonitrile (CAN) content and 30 parts polyvinyl chloride (PVC). The blend has not only good weather as well as ozone resistance but also good oil, fuel. Heat and good compression set.

Elastoflex® NV3360 is a mechanically fully-fluxed blend of 70 parts acrylonitrile-butadiene rubber (NBR) with 34% acrylonitrile (CAN) content and 30 parts polyvinyl chloride (PVC). The blend has not only good weather as well as ozone resistance but also good oil, fuel. Heat and good compression set.

Elastoflex® NV3360 is a mechanically fully-fluxed blend of 70 parts acrylonitrile-butadiene rubber (NBR) with 34% acrylonitrile (CAN) content and 30 parts polyvinyl chloride (PVC). The blend has not only good weather as well as ozone resistance but also good oil, fuel. Heat and good compression set.

Performance

- – Air temperature operating range: -30 °C / +110 °C

- – Shore A hardness ranges from 40 to 90

- – Very good temperature resistance

- – High chemical resistance (minerals, oils, greases and non-polar media)

- – Excellent resistance to ozone, ageing and weather

Application

Can be used in automotive hose, cable jackets, O-rings, seals, gaskets, industrial belt covers, shoe soles, and compression molding goods.

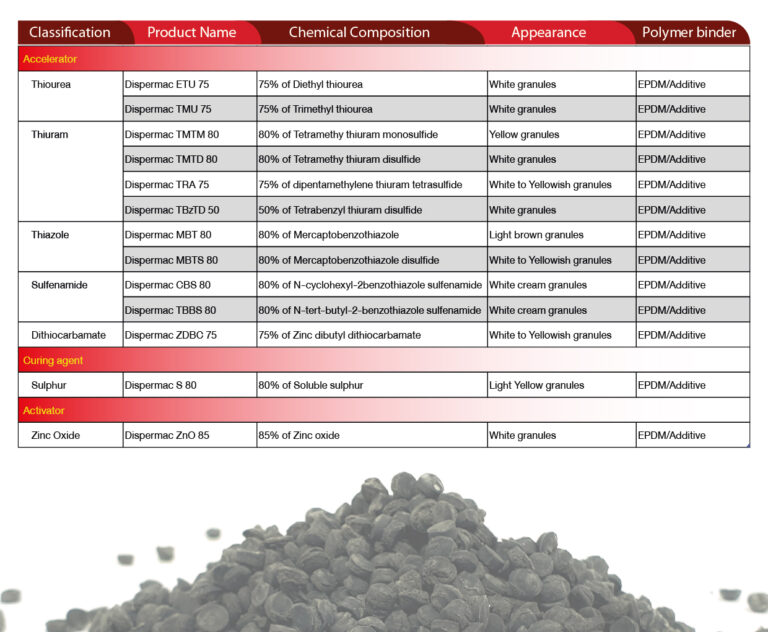

Dispermac™

DISPERMAC™ high performance pre-dispersed for rubber compound makes rubber compounding a breeze.

Dispermac® is engineered with high quality ingredients and state of the art manufacturing process to provide consistency and excellent dispersion, therefore good properties of rubber articles.

In addition, Dispermac® enhances your mixing process by shorten the cycle time, providing dust free process and ease of handling.

Dispermac® is produced from a unique binding system which are compatible with all standard rubber formulation. High quality active chemicals are chosen, then encapsulated by binder thoroughly and evenly, to ensure the best quality masterbatches..

Dispermac® is dispersed quickly into rubber stocks on the open mills or internal mixer. They enhance mixing cycle time without compromising dispersion.

Dispermac® is supplied in free-flowing granules which makes it very easy to handle, weigh and feed. The mixing process can be done with less fuming environment and no waste.

Performance

- – It is in pellet form, making it easy to handle.

- – Excellent dispersion

- – Better operation safety

- – Reduce cycle time.

- – Improve productivity

B: Sustainable Polymers

Our companies are extremely conscious of the environmental impacts of our industries, thus we integrate a contemporary approach to manufacturing. We aggressively pursue improved sustainability not simply to meet expanding customer demand, but also because we believe it is our obligation to enhance production procedures and the goods we design and produce.

Developing new sustainable materials

Our technologist and R&D team are continuing to investigate novel methods of recycling materials and developing more robust materials with longer useful (and reusable) lifespans, as well as more efficient methods of manufacturing at scale.

We aim to be a technological leader in the circular economy and bring about actual change by designing with the entire product lifecycle in mind, including reusability, recyclability, and degradability. We are creating our own revolutionary range of sustainable polymers, some of which are partially manufactured from recycled and recyclable components, some from natural materials, and still others are completely biodegradable.

Product and Service Coverage:

Do you need any help with our products?

Thank you for visiting Innovation group website. Please provide us your personal details for contacting back.