Compounding

Rubber compound manufacturing focuses on producing high-quality rubber compounds at reasonable costs to satisfy customer needs. We optimize the rubber processing facilities and combine their experiences to develop and produce rubber compounds, silicone and fluorosilicone compounds for injection molding, compression molding, and extrusion.

"High-performance mixing technology with an automated feeding system, process tractability, and a flexible semi-automated process."

A: Standard and Customized Compounds

Rubber compounds in black and color for NV, CR, EPDM, NBR, NR, and SBR, along with standard and customized compounds.

Coloured Compounds we can provide compound matched to a RAL and Pantone colour references or to a product sample. Our skilled technologists will be able to provide you with a custom formulation and new development the best formulation.

Natural Rubber: NR

Performance

- Air temperature operating range: -55 °C / +70 °C

- Shore A hardness ranges from 30 to 90.

- Very good dynamic properties

- High tensile strength, elasticity, and rebound resilience

- Good resistance to water, alcohols, glycols, diluted weak acids, and alkaline solutions

Application

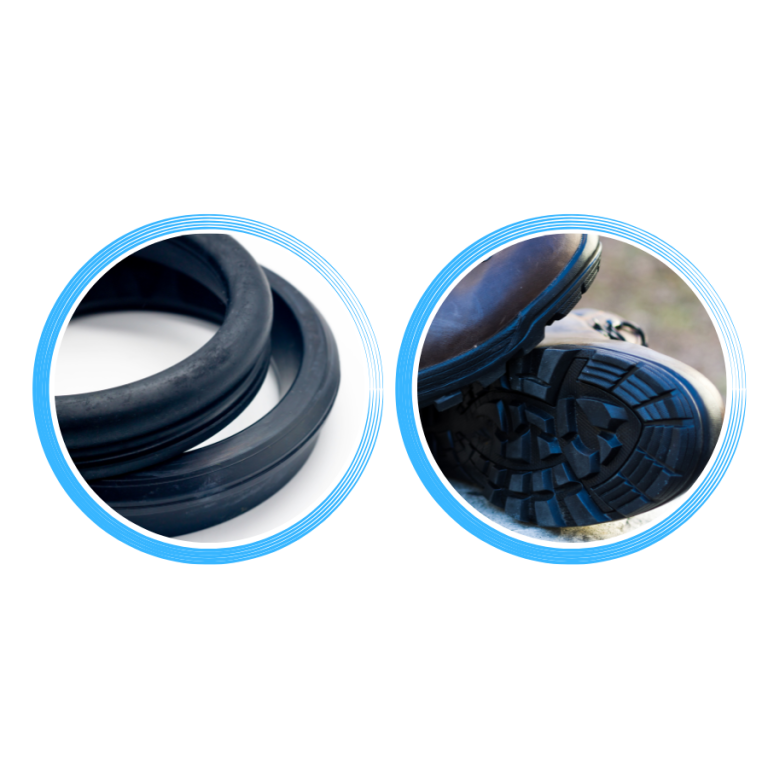

Shoe soles, conveyor belts, flexible couplings, motor bearings, bridge bearings, O-rings, seals and buffers

Styrene butadiene rubber: SBR

Performance

- Air temperature operating range: -45 °C / +90 °C

- Shore A hardness ranges from 30 to 90

- Physical properties similar to natural rubber, heat and ageing resistance

- Abrasion resistance is extremely good.

- Chemical resistance similar to natural rubber

Application

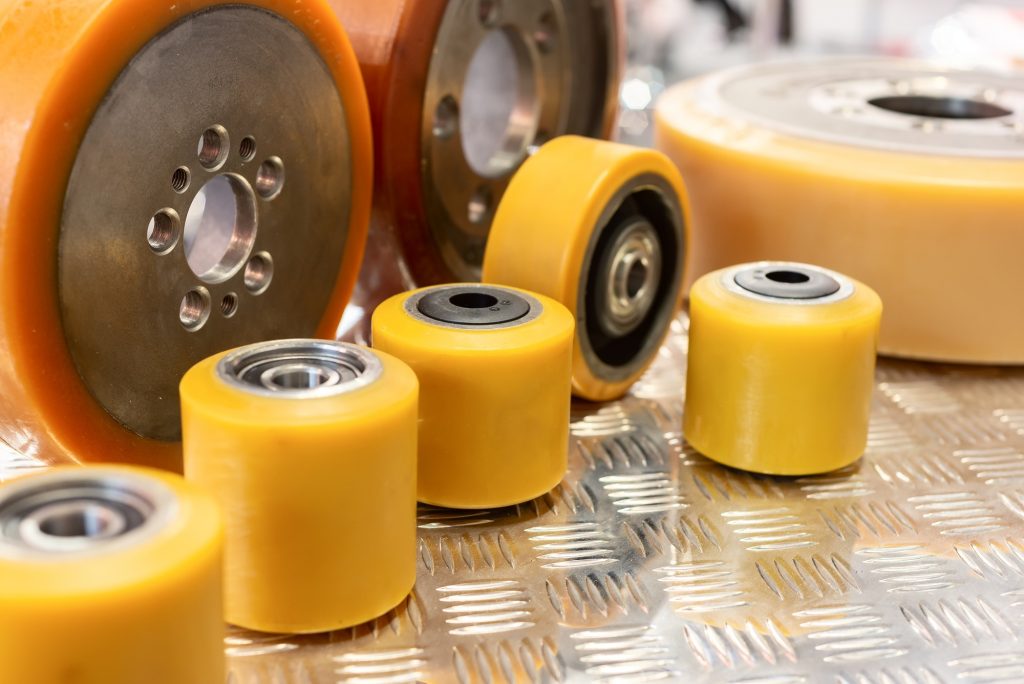

The tire industry is the most prevalent usage, and while it’s also used in shoe soles, cable sleeves, seals, hoses, roller coatings, conveyor belts, and floor coverings.

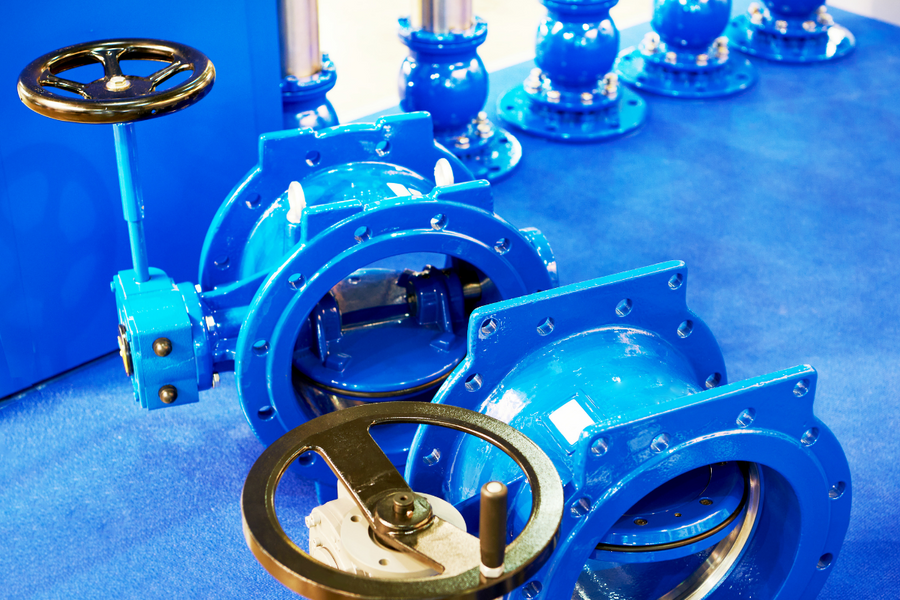

Ethylene-propylene-diene rubber: EPDM

Performance

- Air temperature operating range: -50 °C / +130 °C

- Shore A hardness ranges from 25 to 90

- Excellent ozone, ageing, and weather resistance

- In even high temperatures, low compression set was achievable

- Very good resistance to hot water, steam, acids, alkaline solutions and hydraulic fluids with a glycol-water basis

Application

Examples are seals for windows and doors, hoses for washing machines, dishwashers and water fittings, cable insulations and cable sheathings, use in drinking water, use in seal and control applications.

Nitrile rubber: NBR

Performance

- Air temperature operating range: -30 °C / +110 °C

- Shore A hardness ranges from 30 to 90

- Very good abrasion resistance

- Similar to natural rubber in terms of strength (depending on filler)

Application

Oil- and fuel-resistant seals, membranes, hoses, conveyor belts, rubber-metal bonds, plastic-to-rubber bonded parts, and friction linings are those few examples.

Chloroprene rubber: CR

Performance

- Air temperature operating range: -40 °C / +100 °C

- Shore A hardness ranges from 40 to 90

- High flame resistance

- Good resistance to ozone, ageing and weather

- Good resistance to paraffinic mineral oils and greases, along with refrigerants such as ammonia, and so on.

- Good mechanical properties and elastic behavior at low temperatures

Application

Conveyor belts, seals, hoses, air springs, roller coatings, wiper blades, linings, cable sheathings, and rubber-coated fabrics are also some few examples.

NBR/PVC composite : NV

Performance

- Air temperature operating range: -30 °C / +110 °C

- Shore A hardness ranges from 40 to 90

- Very good abrasion resistance

- Similar to natural rubber in terms of strength (depending on filler)

- Good resistance to oils and fuels

- Good ozone resistance

Application

Oil and fuel resistant seals, membranes, hoses, and conveyor belts are examples.

Butyl rubber : IIR

Performance

- Air temperature operating range: -60 °C / +130 °C

- Shore A hardness ranges from 30 to 80

- Very low gas permeability

- Good resistance to ozone, ageing and weather

- Good resistance to hot water, acids, alkaline solutions and polar solvents

Application

Air hoses, tire inner liners, pharmaceutical stoppers and pipettes, membranes, rubber-coated fabrics, tires bladders are all examples of applications.

B : High Performance Rubber Compounds

Materials of options are high performance elastomers such as FKM, FFKM, HNBR, Silicone (VMQ) , AEM, ACM and ECO.

Fluoro rubber : FKM

Performance

- Air temperature operating range: -30 °C / +220 °C

- Shore A hardness ranges from 55 to 90

- Very good temperature resistance

- High chemical resistance (minerals, oils, greases and non-polar media)

- Excellent resistance to ozone, ageing and weather

- High gas tightness

Application

For example, seals (shaft ring seals, O-rings, tube applications), petroleum industry: down-hole, hydraulic applications, rollers, fuel lines, coatings and compensators for flue gas scrubbers.

Perfluoro rubber : FFKM

Performance

- Air temperature operating range: -5 °C / +320 °C

- Shore A hardness ranges from 75 to 85

- High stability against aggressive media and in polar/non-polar media

- Reliable in both static and dynamic applications

Application

Ideal for demanding seal applications, whenever the customer needs high-quality parts such as O-rings. The unique properties of this material help to maintain seals, which can result in less maintenance, reduced operating costs and improved safety. Only seal elements made of perfluor-elastomer achieve the virtually universal chemical resistance of PTFE, without having to miss the typical sealing, resilience (compression set) and creep resistance of rubber.

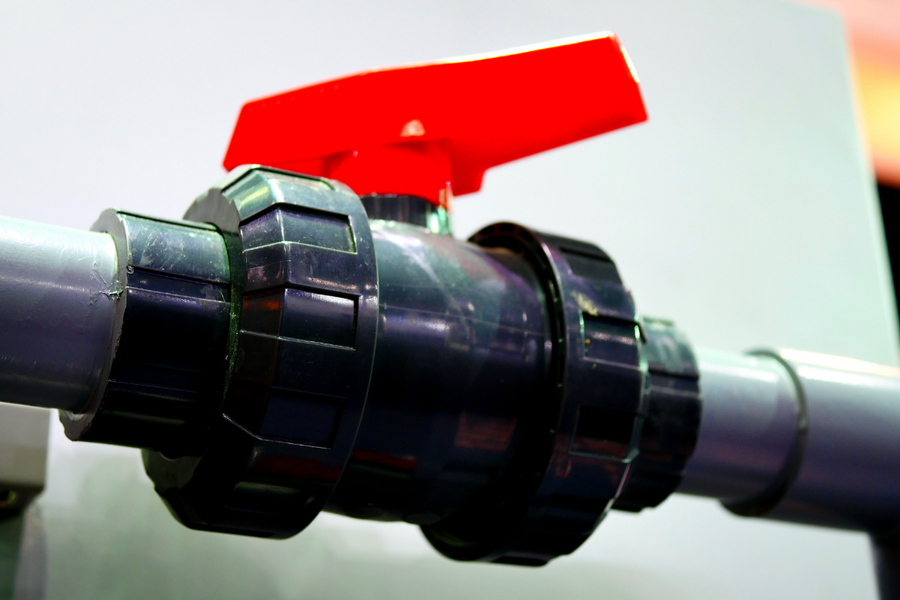

Silicone rubber : VMQ

Performance

- Air temperature operating range: -50 °C / +220 °C

- Shore A hardness ranges from 20 to 90

- High resistance to ozone, ageing and weather

- High heat resistance

- Resistant to mineral oils (non-aromatic), diluted acids and alkaline solutions, alcohols and ketones

Application

Food contact: for example, food production valves, coffee maker seals, and transport hoses. Absorbers, membranes, and other dynamic applications Special applications in nipples for infant bottles, rollers, and etc.

Fluoro silicone: FVMQ

Performance

- Air temperature operating range: -65 °C / +200 °C

- Shore A hardness ranges from 40 to 80

- Very good thermal stability

- Very good low-temperature flexibility

- Excellent resistance to ozone, ageing and weather

- Good resistance to oils and hydraulic fluids

Application

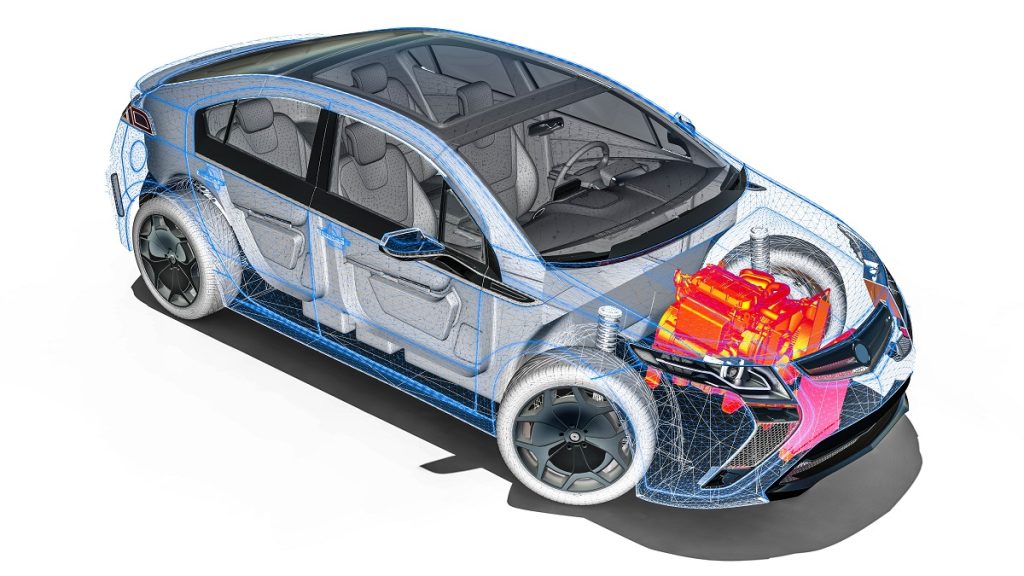

Special seals for the automotive and aeronautics industries with fuel contact, which require excellent low temperature properties.

Hydrogenated nitrile butadiene rubber: HNBR

Performance

- Air temperature operating range: -45 °C / +90 °C

- Shore A hardness ranges from 30 to 90

- Physical properties similar to natural rubber, heat and ageing resistance

- Abrasion resistance is extremely good.

- Chemical resistance similar to natural rubber

Application

The tire industry is the most prevalent usage, and while it’s also used in shoe soles, cable sleeves, seals, hoses, roller coatings, conveyor belts, and floor coverings.

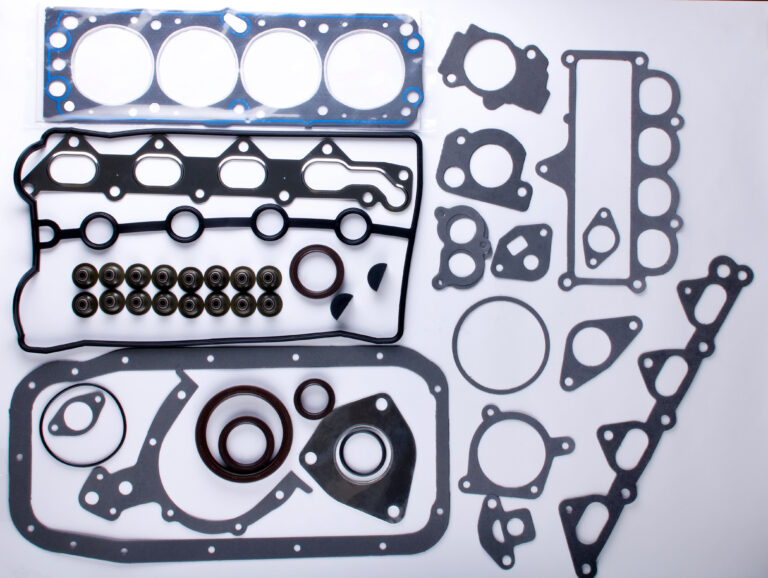

Polyacrylate rubber : ACM

Performance

- Air temperature operating range: -40 °C / +150 °C

- Shore A hardness ranges from 40 to 90

- High resistance in mineral oils, additives and lubricants

- Very good resistance to ozone, ageing and weather

- Good compression set

Application

Is primarily used in automotive and motor construction for cylinder head and oil pan seals, oil hoses, and turbocharger hoses.

Ethylene-acrylate rubbers : AEM

Performance

- Air temperature operating range: -40 °C / +150 °C

- Shore A hardness ranges from 60 to 90

- Very good oil resistance

- Easily flame retardant

- Good damping properties

- Very good resistance to ozone, ageing and weather

Application

Compounds are primarily widely used in the manufacture of oil-resistant compounds and cable insulations. These compounds are also utilized in dampening elements (buffers and absorbers) and flame-proof cables (halogen-free, no caustic combustion products).

Do you need any help with our products?

Thank you for visiting Innovation group website. Please provide us your personal details for contacting back.